Microinverter vs. String Inverter: Which Is Right for Your Solar System?

The inverter is often called the “brain” of a solar energy system. While solar panels capture sunlight, the inverter is the critical piece of technology that converts the sun’s captured raw energy Direct Current (DC) power into usable Alternating Current (AC) power that runs your home and connects to the utility grid. Choosing the right inverter is arguably the most fundamental technical decision you’ll make, impacting your system’s efficiency, cost, monitoring capabilities, and long-term reliability.

The debate today centers on two core architectures: the centralized string inverter versus the decentralized microinverter. This isn’t a case of one being universally better than the other; rather, it’s a trade-off where the best choice depends entirely on your specific roof, local environmental factors, budget, and priorities. A poor choice can cost you significant energy yield over 25 years, while the right choice maximizes your investment.

This comprehensive guide will provide a head-to-head comparison of microinverter vs. string inverter technology for 2025. We will break down their architecture, analyze performance under real-world conditions like shading, compare lifetime costs, and provide a transparent framework to help you decide which technology is the optimal fit for your residential or commercial solar installation.

What is the Core Difference Between Microinverters and String Inverters?

The key differentiator between these two inverter types is the point of DC-to-AC conversion. This determines how the solar panels are wired together and how power is converted, creating distinct advantages and disadvantages for each system.

How Does a String Inverter System Work? (The Centralized Approach)

A string inverter operates by connecting multiple solar panels in a series like a string of Christmas lights . The DC power from the entire string is collected and fed into a single, large, central inverter unit, typically located on a garage wall or in the basement. This centralized unit then converts the combined DC power into AC power for the home.

- Conversion Point: Centralized (one unit for the entire system).

- Wiring: Panels are wired in series.

- MPPT: Maximum Power Point Tracking is performed at the string level.

How Does a Microinverter System Work? (The Distributed Approach)

A microinverter system operates by attaching a small, dedicated inverter directly to the back of each individual solar panel. Each panel, therefore, becomes its own independent power producer, converting DC power to AC power right on the roof. The resulting AC power from all the panels is then combined before being sent to the main electrical panel.

- Conversion Point: Distributed (one microinverter per panel).

- Wiring: Panels are wired in parallel (AC).

- MPPT: Maximum Power Point Tracking is performed at the individual module level.

How Do Microinverters Mitigate Energy Loss from Shading and Mismatch?

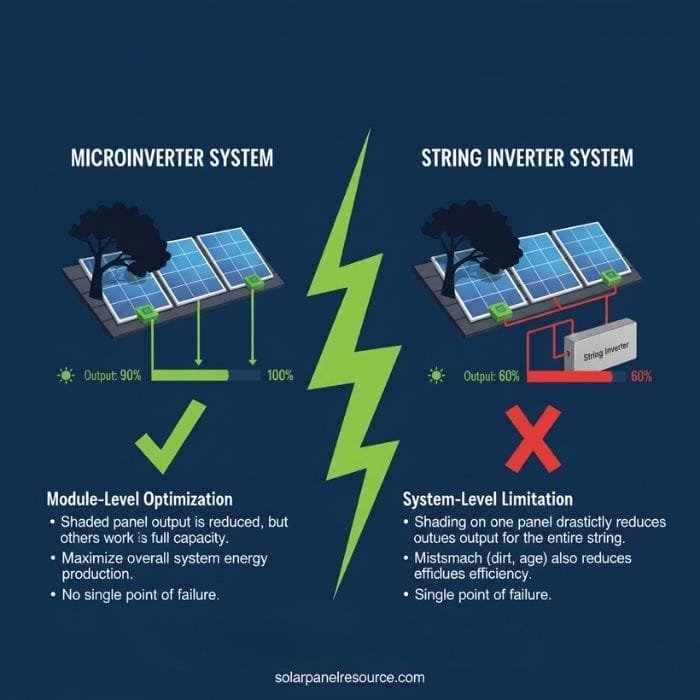

The ability to mitigate power loss from shading is the single biggest technical advantage of microinverters, and the one most often cited for maximizing energy yield in complex scenarios.

What is the “Christmas Light Effect” in String Inverters?

In a standard string inverter system, when one panel in a series is shaded, soiled, or underperforms due to a defect (a concept called panel mismatch), the output of the entire string is often dramatically reduced. This is known as the “Christmas-light effect.” Research by the National Renewable Energy Laboratory (NREL) and other studies indicates that string inverter systems in partially shaded conditions can generate 7% to 26% less annual energy compared to optimized systems.

In fact, the shading of just 10 percent of the area of a string-based PV system could potentially cause a loss of up to 50 percent in its performance due to the entire string being pulled down to the lowest performer’s output.

How Microinverters Solve the Shading Problem

Microinverters eliminate the “Christmas-light effect” entirely because each panel is an independent power producer. Microinverters perform Maximum Power Point Tracking (MPPT) at the individual module level. This means:

- A shaded panel only reduces the output of that specific panel’s microinverter.

- All unshaded panels continue to produce energy at their full, optimal potential, maximizing the overall system’s daily yield.

For installations with frequent or complex shading from trees, chimneys, or multi-faceted roof planes, microinverters are a clear choice and can result in 15% to 35% higher energy harvest during peak shading periods.

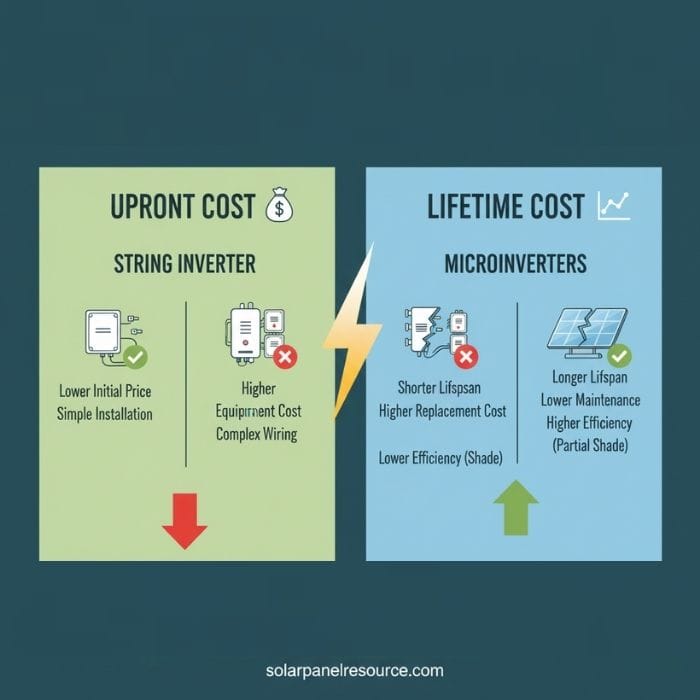

Which Inverter is Cheaper: Upfront vs. Lifetime Cost Analysis

When asking how much do microinverters cost versus string inverters? you must consider both the initial purchase price and the total cost of ownership over the system’s 25-year lifespan.

Initial Equipment Cost Comparison

At first glance, string inverters are the hands-down winner. You are buying one large, centralized component instead of one small inverter for every single panel.

- String Inverter: Lower initial equipment cost. A single string inverter typically costs $1,000 to $4,000 (depending on size).

- Microinverter: Higher initial equipment cost. Buying 20 microinverters for a typical home system will make the initial equipment price 15% to 30% higher than the cost of a single central inverter.

Lifetime Cost and Warranty Comparison

The long-term cost of a string inverter flips the script, often making the microinverter solution more cost-effective over 25 years. This is primarily due to reliability and warranty differences.

- String Inverter: Typically comes with a standard 10 to 12-year warranty. Because solar panels last 25 years, a string inverter will need to be replaced at least once, representing a major service and replacement cost (including labor) halfway through the system’s life.

- Microinverter: Leading microinverter manufacturers offer a standard 25-year warranty, designed to match the lifespan of the solar panels themselves. This eliminates the major replacement cost and service call required by a string inverter at year 12.

When the Levelized Cost of Energy (LCOE) is considered, the reliable, long-life microinverter can often reach the break-even point more quickly, despite its higher initial cost.

Head-to-Head Comparison: Microinverter vs. String Inverter Specs

This table summarizes the core operational and financial differences between the two technologies, providing a transparent view of the trade-offs.

| Factor | Microinverter (Distributed) | String Inverter (Centralized) |

| Shading Impact | Minimal. Only shaded panel is affected; unshaded panels produce full power. | Significant. Shading on one panel reduces the output of the entire series string. |

| System Efficiency | Excellent real-world performance; achieves higher annual yield in complex roofs/shading. | Higher theoretical peak efficiency (97-99%); but lower real-world efficiency due to shading losses. |

| Monitoring | Module-level monitoring. View performance of every single panel. | System-level monitoring. View total string output only. |

| Warranty/Lifespan | 20-25 years. Designed to last the life of the panels. | 10-12 years. Requires mid-life replacement. |

| Safety | High. Converts to low-voltage AC on the roof; no high-voltage DC on roof or running through conduit. | Lower. High-voltage DC is generated on the roof and runs to the centralized inverter. |

| Scalability | Excellent. Easy to add panels later without redesigning the entire system. | Poor. Adding panels often requires resizing or replacing the central inverter. |

How Do Safety and Reliability Differ Between Inverter Types?

Safety is a critical solar system reliability factor that must be addressed, particularly for residential installations. Microinverters offer clear advantages in electrical safety.

The Electrical Safety Advantage of Microinverters

Microinverters convert the panel’s DC power to AC power directly at the source (the panel). This means that only low-voltage AC power runs from the roof through the conduits to your electrical panel. String inverters, by contrast, run high-voltage DC power (often 300-600 volts) through the home from the roof to the inverter location. This high-voltage DC current poses a greater risk in the event of a damaged wire or a fire, as high-voltage DC is notoriously difficult for fire crews to turn off quickly. The move toward module-level power electronics (MLPEs) like microinverters aligns with advanced safety standards in many modern building codes.

Reliability and Troubleshooting

While microinverters are mounted outdoors and therefore subject to more environmental stress, modern designs have resulted in high reliability. The main advantage here is diagnostics:

- Microinverter Troubleshooting: Because the system provides module-level monitoring, if a panel underperforms, the installer can pinpoint the exact faulty panel from the ground via software, saving time and labor costs.

- String Inverter Troubleshooting: If the centralized inverter reports a drop in total production, the installer must physically go on the roof to test each panel to find the fault, making maintenance time-consuming and expensive.

Which Inverter is Right for Your Solar System?

The choice between a microinverter vs. string inverter ultimately depends on balancing your budget against your roof’s complexity and your long-term priorities.

Who Should Choose Microinverters?

Microinverters are the optimal choice for installations where energy harvest is paramount due to physical constraints.

- Complex Roofs or Shading: If your roof has multiple planes, varying orientations (east/west-facing), or is subject to shading from chimneys, vents, or trees, the microinverter’s module-level MPPT will generate significantly more energy over the system’s lifespan.

- Need for Module-Level Monitoring: If you want detailed performance data for every single panel and quick, targeted troubleshooting.

- Safety Priority: If reducing high-voltage DC wiring is a primary safety concern.

- Future Expansion: If you plan to add more panels to different parts of your roof later, microinverters make this scalability simple.

Who Should Choose String Inverters?

String inverters remain the best choice for simple, large, unshaded arrays where initial cost savings are a priority.

- Simple, Unshaded Roofs: If you have a large, single-plane roof with no shading issues and a consistent south-facing orientation, a string inverter will achieve its high theoretical efficiency with the lowest initial cost.

- Large Commercial Projects: For very large, simple installations (typically over 10 kW), the cost-per-watt savings often favors string inverters.

- Budget Constraint: If the initial higher upfront cost of microinverters is prohibitive.

A third option, the DC power optimizer, acts as a middle ground: it provides module-level MPPT (like a microinverter) but keeps the central string inverter (like a string inverter). These systems offer performance similar to microinverters but retain the single point of AC conversion.

Making the Informed Choice

The inverter choice is the most influential technical decision in your solar project. While the initial equipment cost of a string inverter is lower, the microinverter often provides superior lifetime value, safety, and energy yield in real-world residential environments due to its resilience to shading and its longer, comprehensive warranty. Before making a final decision, a thorough site assessment by a qualified installer is mandatory to determine the best technology for your specific roof and energy goals. Choosing the right inverter ensures you are investing in a safe, high-performing system that maximizes your energy independence for decades to come.

Solar Energy Enthusiast & Renewable Energy Researcher

Vural’s journey into solar energy began four years ago, driven by frequent power outages and high electricity bills at his own home. He has since gained hands-on experience with both personal and commercial solar projects. At solarpanelresource.com, Vural shares his real-world insights and in-depth research to guide homeowners and business owners on their own path to energy independence.