How to Clean and Maintain Solar Panels for Maximum Efficiency ?

While solar panels are engineered to be a reliable and low-maintenance source of power for decades, their performance can decline significantly when routine cleaning and maintenance are overlooked. It’s a bit like a car; it will run without an oil change, but not for long, and certainly not at its best.

According to research published by the National Renewable Energy Laboratory (NREL), the world’s leading authority on solar energy, accumulated dust, organic matter, and even industrial pollutants can lead to an energy yield loss ranging from 5% to a staggering 25%. I’ve personally seen this firsthand in my years in the industry, where a simple cleaning job brought a system’s output back from the brink. This loss of efficiency isn’t just a number on a chart; it directly impacts your energy savings and the return on your investment.

Adopting a structured maintenance program and using industry-approved cleaning methods is essential to achieving and maintaining maximum efficiency. This proactive approach not only ensures you get every kilowatt-hour you paid for but also protects the long-term value of your investment, which is a key reason many people choose solar in the first place.

Why Regular Cleaning Is Essential

Surface soiling is one of the most common—and often underestimated—reasons for a drop in solar panel performance. When dirt, dust, pollen, or other debris accumulates on the glass, it reduces the amount of sunlight that can reach the photovoltaic cells. This leads to a lower current output, which is a direct hit to your system’s efficiency. But the problems don’t stop there. Soiling can also cause an increase in cell temperatures, which can accelerate the degradation of protective coatings and reduce the lifespan of your panels.

Industry guidelines consistently emphasize that regular cleaning is not just a suggestion; it’s an essential part of a smart maintenance plan. Cleaning removes these obstructions and restores optimal light transmittance. By maintaining clean surfaces, operators can ensure that their panels operate much closer to their rated capacity, improving both short-term output and protecting the longevity of their entire system. Don’t underestimate the power of a clean panel—it’s one of the simplest and most effective ways to boost your system’s performance and protect your investment.

Recommended Cleaning Frequency

There’s no one-size-fits-all answer for how often you should clean your solar panels. Experts consistently advise tailoring cleaning intervals to your specific site conditions. This isn’t just a best practice; it’s a way to ensure you’re not wasting time or money on unnecessary maintenance. The best approach is to use your system’s performance monitoring data to tell you when it’s time for a cleaning.

Regularly reviewing your monitoring system is key to detecting drops in output that indicate soiling. While you should check this data frequently, there are some general benchmarks you can use to get started:

- Arid and Agricultural Regions In regions with low rainfall and a lot of airborne dust—like deserts or agricultural areas—soiling can happen quickly. In these environments, cleaning every **8–12 weeks** is often recommended to prevent significant performance loss. The fine dust and pollen can accumulate rapidly and create a layer that is difficult for rain to wash away.

- Urban Installations City environments present their own challenges, with pollutants, traffic dust, and bird droppings. For most urban installations, cleaning approximately **twice per year** is a good starting point. This schedule helps manage the buildup of urban grime and ensures your panels are performing well in both spring and fall.

- High-Rainfall Areas In areas with frequent and heavy rainfall, nature often does a lot of the work for you. In these climates, an **annual inspection** is usually sufficient, with cleaning only necessary if your performance data shows a noticeable decline. Rain is a powerful, free cleaner, and in these regions, you can rely on it to keep your panels in good shape.

For advanced operators of large-scale systems, a more precise approach is recommended. These systems often integrate **SCADA data** or dedicated soiling sensors that provide real-time performance feedback. These tools can automatically trigger a cleaning schedule when output deviations exceed preset thresholds, which are commonly set at a **3–5% drop** below expected performance. This data-driven method ensures maintenance is only performed when it’s genuinely needed, optimizing both efficiency and cost.

Approved Tools and Materials

Module manufacturers are very clear about what materials to use for cleaning to prevent damage to the glass and the delicate anti-reflective coatings. Using the wrong tools can not only hurt your system’s performance but can also void your warranty, which is a risk you never want to take.

For this reason, industry best-practice guidelines are specific about the recommended tools:

- Soft microfiber cloths or soft-bristle brushes are ideal for gently scrubbing away stuck-on grime.

- Low-pressure deionized or distilled water systems are preferred because they prevent mineral deposits and water spots from forming on the glass, which can reduce efficiency over time.

- Mild pH-neutral detergents are recommended for stubborn residues like bird droppings.

On the other hand, certain tools must be avoided at all costs. High-pressure washers, abrasive sponges, and harsh chemicals should never be used. These methods can scratch the surface of the glass, remove the crucial anti-reflective coatings, or even force water into the laminate layers, causing long-term damage that is not covered by your warranty.

As confirmed by the SolarPower Europe Operations and Maintenance Best Practice Guidelines, using a soft-bristle brush, deionized water, and a mild detergent is the safest and most effective way to clean your solar panels. This simple, professional approach ensures your system remains in top condition for years to come.

SolarPower Europe Operations and Maintenance Best Practice Guidelines.

Safe Cleaning Procedures

Cleaning solar panels may seem like a simple task, but it requires strict adherence to safety protocols to prevent both personal injury and costly equipment damage. The first and most critical step before starting any work is to shut down both the AC and DC circuits of your system. This must be done according to the manufacturer’s instructions. For larger commercial installations, it’s also essential to apply lockout/tagout procedures to ensure the system cannot be accidentally re-energized while work is being performed. This simple step eliminates the risk of electrical shock.

Timing is also crucial. Cleaning should always be performed during cooler hours—early morning or late evening—to reduce the risk of thermal shock. Pouring cold water onto hot panels can cause the glass to crack, a very expensive mistake that is not typically covered by warranty. Working during these times also minimizes glare, making the job safer and more comfortable for the maintenance team.

Finally, proper personal protective equipment (PPE) is non-negotiable. Whether you’re working on a rooftop or a large ground-mounted array, always use fall protection harnesses, non-slip footwear, and gloves. These basic precautions are vital to ensuring that the maintenance of your solar system is both effective and safe.

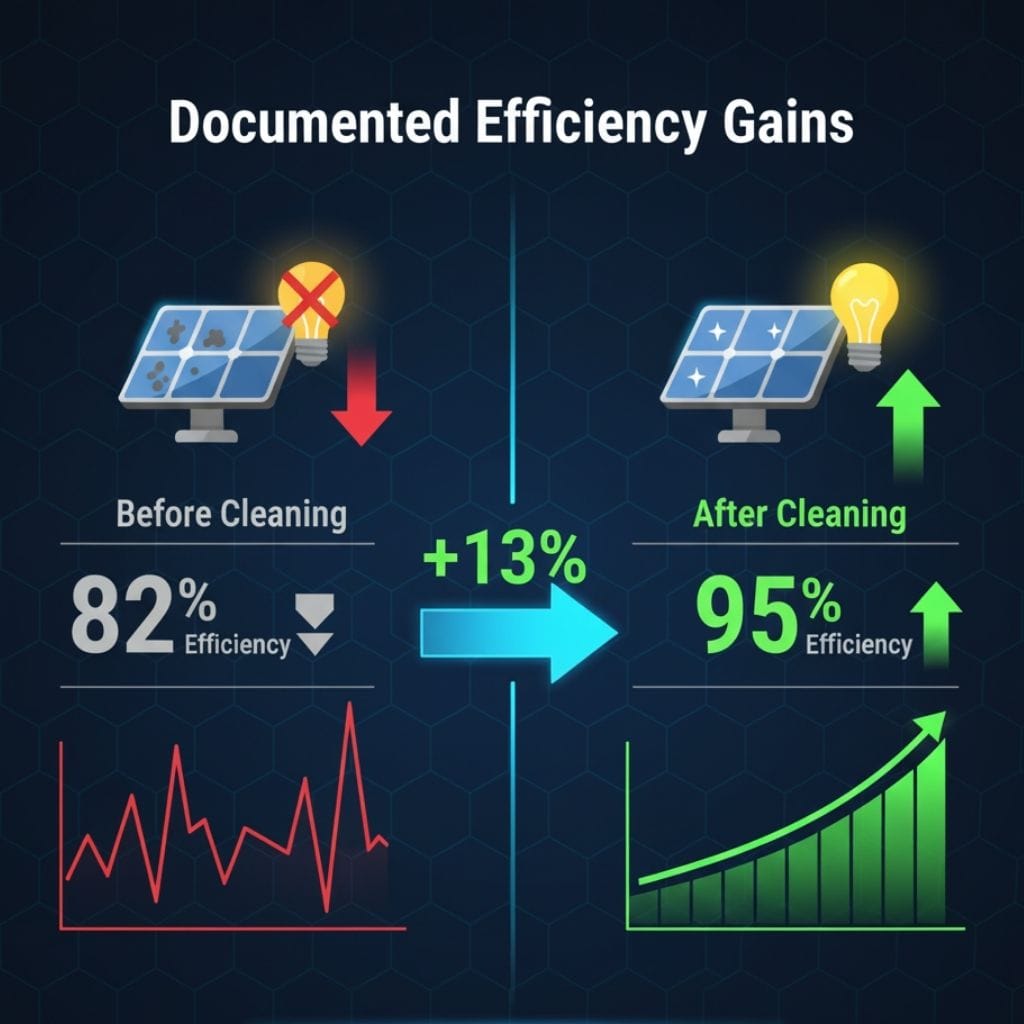

Documented Efficiency Gains

The value of proper solar panel cleaning isn’t just a theory—it’s confirmed by hard data from real-world field studies. A report published in the journal Renewable Energy provided a clear example of this. In a study of panels in a semi-arid climate, systems that were cleaned quarterly achieved a remarkable 14–17% higher annual energy output compared to systems that were neglected. This significant boost in production directly translates into higher energy savings and a faster return on investment.

Even in more forgiving climates, the benefits are still substantial. In moderate climates where soiling is less of a concern, cleaning can still lead to production improvements of 3–5%. While this might seem like a small number, it can translate into significant cost savings over the lifespan of the system and, for commercial and residential installations alike, a shorter payback period.

Ultimately, neglecting to clean your panels is like leaving money on the table. The data from these studies provides a powerful, evidence-based argument that proactive maintenance is not an expense—it’s a smart investment that ensures your solar system performs at its best, providing maximum financial and environmental returns.

Maintenance Beyond Cleaning

Cleaning is a critical part of solar maintenance, but it’s just one piece of the puzzle. To sustain maximum efficiency and protect your investment for the long term, a comprehensive maintenance program is essential. Think of it like getting a yearly check-up for your car; you’re not just topping off the fluids, you’re looking at everything under the hood.

A full maintenance program should include:

- Thermal imaging to detect hot spots or cell defects. These can signal microcracks or other internal issues that are invisible to the naked eye.

- Torque checks on mounting structures to ensure mechanical integrity. Over time, wind, snow, and temperature changes can cause bolts to loosen, potentially compromising the safety and stability of your entire array.

- Inspection of connectors, junction boxes, and cabling for any signs of corrosion or wear. Poor connections can lead to significant energy loss and are a major fire hazard.

- Firmware updates and inverter log reviews. Modern inverters are smart devices. Ensuring their software is up to date and reviewing their logs can help identify performance issues before they become major problems.

- Shading analysis to identify new obstructions from vegetation or construction. A simple tree growth from one year to the next can reduce your output more than you think.

These tasks should be performed at least annually by a qualified professional. Proper documentation of this maintenance is not only crucial for operational audits but is often required to keep your warranty valid..

Role of Professional Inspections

While visual inspections and basic cleaning are a great start, a professional solar technician brings a higher level of expertise and specialized tools to the table. These experts have access to advanced diagnostic equipment that can catch problems long before they lead to a significant drop in performance.

For example, a certified technician can use an I-V curve tracer to measure the current and voltage of your panels. This tool creates a detailed graph that can immediately reveal hidden issues like cell defects, poor connections, or partial shading that isn’t obvious to the eye. Even more advanced is electroluminescence imaging, which allows a technician to see micro-cracks and other internal damage that are invisible under normal light. They can also detect Potential-Induced Degradation (PID) and insulation faults that can severely impact a system’s long-term output.

These professional inspections aren’t just for your peace of mind; they’re often a warranty requirement. Many manufacturers require proof of professional maintenance at defined intervals to maintain full warranty coverage. This is a critical point that many system owners overlook. By investing in a professional inspection, you are not only ensuring your system performs at its best but also protecting the financial security of your long-term investment.

Risks of Improper Cleaning

While cleaning solar panels is a vital part of maintenance, it’s just as important to use the right methods. Using improper cleaning techniques can cause permanent and irreversible damage to your modules, completely defeating the purpose of the cleaning in the first place.

For instance, using a high-pressure water washer might seem like an easy way to blast off dirt, but it’s a major risk. The powerful spray can drive moisture under the protective laminate layers of the panel, leading to delamination and internal corrosion. This kind of damage is not only costly to repair but can also void your manufacturer’s warranty.

Similarly, using abrasive materials like steel wool or a rough brush can scratch the glass surface of the panels. These tiny scratches, while they might seem insignificant, permanently reduce light transmission and efficiency over time. They also make the panels more susceptible to dirt buildup.

To avoid these costly mistakes, always follow the manufacturer’s specific guidelines and industry standards. A mild, pH-neutral detergent and a soft-bristle brush, combined with low-pressure water, are the safest and most effective tools for the job. Adhering to these simple rules is critical to protecting your investment and ensuring your solar panels continue to perform at their best for their full lifespan.

Monitoring and Performance Tracking

One of the most powerful tools in a solar system owner’s arsenal is a modern monitoring platform. These platforms track your system’s output in real time, providing invaluable data that can tell you a lot more than just how much power you’re generating.

By comparing your actual energy production against irradiance-adjusted models, these platforms can immediately detect when cleaning or additional maintenance is needed. An irradiance-adjusted model takes into account the amount of sunlight your panels are receiving in real time, factoring in cloud cover and seasonal changes. If your system is consistently producing less than what the model predicts—a persistent performance gap—it’s a clear signal that something is wrong.

This kind of proactive monitoring ensures that a small issue, like a layer of dust or a minor wiring fault, doesn’t lead to significant energy losses over time. Instead of waiting months to notice a problem, you can take immediate action to address the issue, ensuring your system is always operating at its peak efficiency. It turns a potential problem into a quick fix, protecting both your energy output and your financial investment.

Environmental and Seasonal Factors

A successful solar maintenance plan is never a one-size-fits-all solution; it must be tailored to the local environment. The specific conditions of your site will have a major impact on what your cleaning strategy should be.

For example, a solar system located at a coastal site will require more frequent rinsing. Salt deposits from sea spray can build up on the panel glass, forming a film that reduces light transmission. A simple rinse with fresh, clean water is often enough to prevent this from becoming a significant issue.

In contrast, systems in industrial regions may experience different kinds of residues, such as oily films or sticky soot. These residues are often more difficult to remove than simple dust and will require the use of a manufacturer-approved detergent. A simple water rinse won’t be sufficient in these cases.

Finally, in snowy climates, the cleaning strategy is less about washing and more about design. Panels in these regions are typically installed at a steeper angle to encourage natural snow shedding. Mechanical snow removal is highly discouraged, as it can easily scratch the glass and void the warranty.

By adjusting your maintenance plans for these specific variables, you can ensure your solar system stays efficient and productive year-round, no matter where it is located. It’s a crucial step in protecting your investment for the long term.

Cost and Return on Investment

While you can handle basic cleaning yourself, hiring a professional service is often a worthwhile investment. These services typically cost between $5 and $15 per panel, with the final price depending on factors like the complexity of the roof, the pitch of the panels, and the overall site conditions. But studies consistently show that these costs are often recovered within just one or two billing cycles through improved energy production.

For residential systems, this means the money you spend on cleaning is quickly returned to you through lower electricity bills. For commercial and utility-scale systems, the financial benefits are even more significant. Regular cleaning and maintenance directly reduce downtime, protect the long-term asset value of the entire array, and support the overall financial performance of the project.

In a world where every percentage point of efficiency matters, professional maintenance is not an expense—it’s a crucial part of a smart business strategy that ensures your solar assets are generating maximum revenue and providing a strong, reliable return on investment.

Best Practices for Solar Panel Maintenance: A Summary

Keeping your solar panels in top condition doesn’t have to be complicated. By following a few key best practices, you can ensure your system delivers maximum performance for its entire lifespan. Think of these as the fundamental rules for protecting your solar investment.

- Follow Manufacturer Guidelines Your solar panels came with a manual for a reason. Always follow the manufacturer’s specified cleaning and maintenance procedures. This is the single most important rule to ensure safety and maintain your warranty.

- Use the Right Tools for the Job Avoid harsh chemicals and high-pressure washers, which can cause permanent damage. Instead, use only **approved materials and low-pressure water systems**. A soft-bristle brush and a mild, pH-neutral detergent are usually all you need to get the job done right.

- Let the Data Guide You Don’t just guess when it’s time to clean. Use your system’s performance data to guide you. Base your cleaning frequency on **monitored performance data**, which can alert you to a drop in efficiency caused by soiling. This ensures you only clean when it’s necessary, saving you time and money.

- Schedule Professional Inspections While you can handle basic cleaning, leave the complex checks to the experts. Schedule professional inspections annually or biannually to detect hidden issues like micro-cracks or wiring faults. A professional’s expertise and specialized equipment are invaluable for long-term system health.

- Document Everything Finally, always keep detailed records of all maintenance activities. This documentation is essential for tracking your system’s performance over time and, most importantly, for **maintaining your warranty coverage**. Think of it as your solar system’s health record.

By making these practices a part of your routine, you can ensure your solar panels continue to perform efficiently, providing you with clean, reliable energy for decades to come.

Maintaining solar panels according to industry best practices is absolutely essential to ensure maximum efficiency. It’s an investment, not just in technology, but in long-term performance. Research from leading bodies like the National Renewable Energy Laboratory (NREL) and guidelines from expert organizations confirm that a proactive approach pays off significantly.

Regular cleaning, routine inspections, and strict adherence to approved methods are not just minor tasks—they’re the core of a smart maintenance strategy. This comprehensive approach directly improves your system’s energy yield, protects your warranties from being voided, and extends the overall operational lifespan of your photovoltaic system. By implementing these simple, yet critical, procedures, you secure a reliable source of renewable energy and protect the financial value of your long-term investment.

You can also review our article titled What Is a Solar Panel and How Does It Work? to get full information.

Solar Energy Enthusiast & Renewable Energy Researcher

Vural’s journey into solar energy began four years ago, driven by frequent power outages and high electricity bills at his own home. He has since gained hands-on experience with both personal and commercial solar projects. At solarpanelresource.com, Vural shares his real-world insights and in-depth research to guide homeowners and business owners on their own path to energy independence.